From Elements to Efficiency: The Full Option for Mining Equipment Parts

Unveiling Important Mining Devices Parts for Ideal Workflow

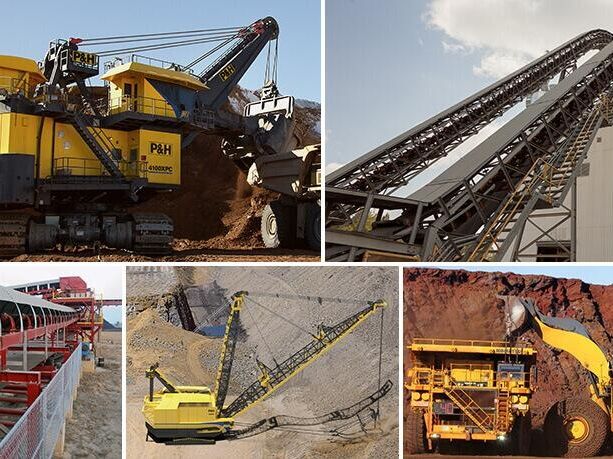

In the complex world of mining procedures, the smooth performance of tools is critical. As we dig into the midsts of mining equipment fundamentals, a better look at the intricate information and capabilities of these components introduces a fascinating globe where effectiveness and integrity are the foundations of success.

Relevance of Correct Drill Bits

Appropriate choice and upkeep of drill bits are basic for taking full advantage of mining effectiveness and efficiency (mining equipment parts). The type of drill bit selected must align with the certain geological problems of the mining website to make sure ideal performance.

Routine maintenance of drill bits is equally important to ensure durability and effectiveness. Damaged or plain drill little bits can cause reduced drilling speed, raised endure boring equipment, and inevitably, lowered efficiency. Maintenance jobs may consist of honing, regrinding, or replacing used components to keep the drill bits in top functioning condition.

Key Elements in Conveyor Solutions

Effective material transport in mining operations greatly counts on the performance and integrity of crucial parts in conveyor systems. One crucial part is the conveyor belt itself, which brings the products along the mining website.

Crucial Filters for Devices Maintenance

A crucial facet of making certain the long life and optimum efficiency of mining equipment hinges on the meticulous option and upkeep of important filters. Filters play a crucial function in securing mining equipment from pollutants that can trigger deterioration, causing pricey repairs and downtime. Dirt, dust, and debris are pervasive in extracting atmospheres, making the correct filtering system important to tools resilience.

Filters in mining tools serve to trap bits that could infiltrate delicate parts such as transmissions, engines, and hydraulics. Consistently replacing read review these filters according to maker referrals is critical to avoid blocking and make sure effective procedure. Disregarding filter upkeep can cause reduced tools life-span, lowered performance, and enhanced fuel usage.

Important Use Parts for Crushers

In the world of mining devices maintenance, one crucial facet that requires focus is the identification and replacement of essential wear parts for crushers. Crushers play a basic role in the ore processing and worldly reduction processes within mining operations. Some of the key wear components that are essential for the effective functioning of crushers include the complying with:

** Crusher Liners **: These are crucial in securing the crusher covering from deterioration triggered by the material being squashed.

** Jaw Layers **: Found in jaw crushers, these parts are in charge of crushing the material versus a taken care of surface area.

** Mantles and Concaves **: These components are vital in gyratory crushers, where they help in crushing the product into an extra refined form.

Routine evaluation and replacement of these wear components are vital to guarantee the crushers operate at their optimal effectiveness, reducing downtime and making the most of productivity in mining operations. Proper these details upkeep of these wear components can dramatically influence the overall efficiency and long life of the crushers, ultimately adding to the success of mining activities.

Role of Hydraulic Cyndrical Tubes in Mining

Playing a crucial function in modern mining procedures, hydraulic cylinders are important parts that facilitate the effective functioning of various heavy machinery. These hydraulic cyndrical tubes are crucial for powering crucial mining equipment such as excavators, loaders, drills, and bulldozers.

Hydraulic cyndrical tubes in mining devices are created to hold up against severe operating problems, including extreme temperatures, high stress, and heavy tons. In significance, hydraulic cylinders play an important duty in improving the effectiveness and performance of mining operations worldwide.

Conclusion

Finally, it is vital for extracting procedures to make use of appropriate drill little bits, key elements in conveyor systems, vital filters for equipment maintenance, crucial wear parts for crushers, and hydraulic cyndrical tubes. These essential mining equipment parts play a considerable duty in making sure ideal operations and making the most of effectiveness in the mining sector. By purchasing trustworthy and top quality devices parts, mining companies can enhance performance and minimize downtime, eventually causing a much more successful procedure.

In the complex globe of mining procedures, the smooth functioning this page of equipment is critical. By investing in exceptional purification systems and adhering to a rigorous maintenance timetable, mining operations can enhance equipment reliability, minimize downtime, and eventually maximize efficiency.

In the world of mining tools maintenance, one crucial aspect that requires attention is the recognition and replacement of crucial wear parts for crushers. These crucial mining tools components play a significant function in making best use of and guaranteeing optimum operations effectiveness in the mining sector. By investing in reputable and high-grade equipment parts, mining business can boost productivity and reduce downtime, inevitably leading to an extra successful operation.